Building a screen printing press – Part 1

An introduction

When first introduced to screen printing, one may be easily inclined to believe that it can be done with minimal equipment. Images spring to mind of a wooden frame, t-shirt and squeegee, and how easily one might bring those three things together to print some shirts. This might be true to an extent, but one will never achieve a professional look without the right equipment.

At a minimum, the equipment one will need for a high volume good quality screen printing, is

- One or more frames. (wood or aluminium)

- 43 per cm (~110 per inch) mesh material. (no substitute for this)

- Apparatus for stretching mesh material tightly over frames to make screens.

- Screen drying racks in an area protected from direct light.

- One or (probably) more squeegees of various sizes.

- Water based or plastisol screen printing inks in the required colours.

- A pressure washer. (hosepipes won’t do the trick)

- A washout booth. (a bath with a shower head will do fine)

- A computer to edit and create designs.

- Transparencies or equivalent printable films to hold negatives.

- A printer capable of printing films in opaque ink. (quality inkjet is good)

- Light sensitive emulsion to coat your screens. (vinyl may be used for simple designs)

- A UV exposure unit. (sunlight is not constant strength, or dependable)

- Chemicals such as emulsion remover, paint thinner and degreaser.

- A screen printing press to hold your frames securely and accurately.

- A flash dryer or heat press to cure the ink after printing.

That’s a lot of equipment right there. Clearly it’s not just a matter of screen, squeegee and shirt!

Nevertheless, it is quite possible for an at least partially DIY approach to be really successful. Here we will be looking at one possible way to build just one of your needs, the screen printing press.

Why make your own?

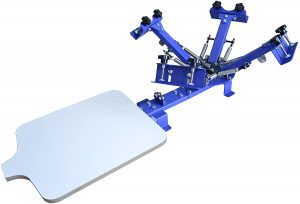

Printing presses, especially those suited for t-shirts, are readily available. Both single screen and multiple 4, or 6 colour presses may be found. These professional presses will give great results, but they generally have two down sides: They can be very costly, and take up a lot of space.

Designs for these presses are normally rather standard, but features such as the number of platens, or micro registration facilities, etc. may vary.

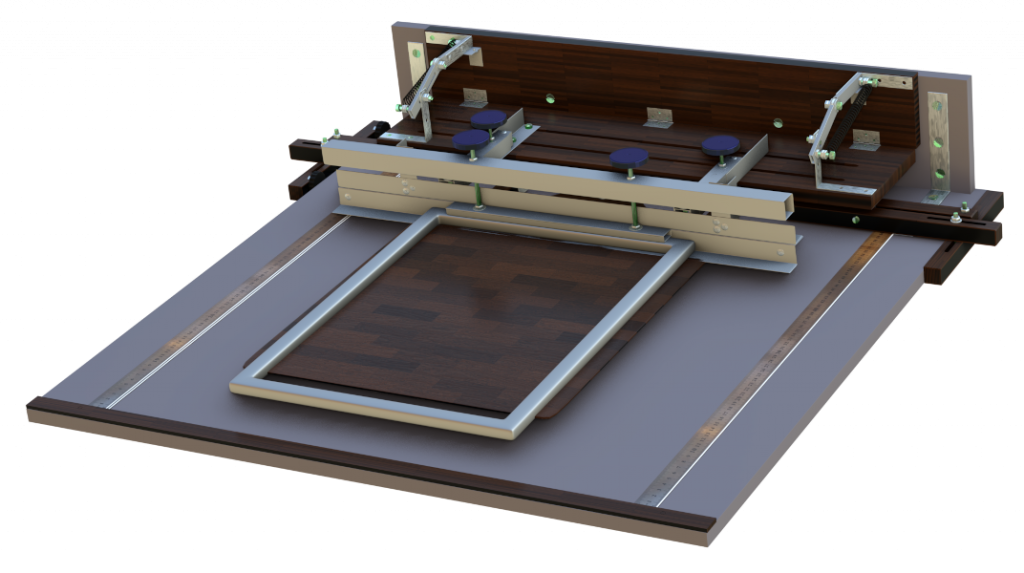

Building your own press allows one to reduce costs and choose the features you need. In our case, we wanted support for multiple colours and multiple platens, but need this supported in a single portable workstation. We also wanted to support hats and other non-conformant objects in our press in addition to t-shirts.

Requirements for a screen printing press

A screen printing press provides a way to hold a t-shirt or other object or garment securely in place, and a way to securely mount a frame and position it directly over the area to be printed. The distance between the frame and the printed surface (or platen/palette) is important; too close and the mesh will not separate properly from the surface, but too far means too much pressure will be applied to the mesh from the squeegee, forcing too much ink through the mesh.

When we use the word “securely”, it cannot be stressed enough that the platen and the frame should not move at all between prints. Any variation in the position of the frame or platen will mean blurry and imprecise prints. This is also the reason why the mesh must be stretched so tightly over the frame.

So the task is to produce a mechanism which accomplishes the above as simply and cheaply as possible. There are numerous ways to accomplish these goals- our way is but one method.

These are the parts that make up our screen printing press:

- The table surface and back plane

- The height adjustment and swing mechanism

- Spring loaded lift and lowering position retainers

- The screen swapping and registration system

- Frame holder and clamping system

- Adjustable platen holder

- Multiple platens

- Screen tensioning over frames

0 Comments