Vinyl Cutting

Vinyl has become increasingly popular as a way of making and transferring images, especially in the hobbyists market.

There are various kinds of vinyl readily available, from sticker vinyl which may be printable or patterned, to heat transfer vinyl used to apply images to t-shirts or other apparel. Sheets of vinyl are available in rolls or by length at very affordable prices.

Although vinyl often has a uniform colour or pattern, and may have a metalic or irridescent sheen, or even glow in the dark, one may achieve extrordinary effects by creatively layering colours in a design.

Vehicle sticker vinyl may be used to produce stickers for branding. The stickers are carefully applied to the vehicle using a small squeegee to ensure that no air bubbles remain trapped under the vinyl.

Glint Concepts is not geared for all kinds of vehicle branding, and you may be better off with someone who specialises in this, but we are willing to take on smaller jobs, such as the truck on the right.

The process for making vinyl t-shirt heat transfers involves a few steps, and depending on how complex the design, this may be quite a labour intensive process.

- First we select or create graphic art that we want to use in our end product. This artwork must be scaled to the right size. Raster based art is not easily sized, so in this stage we prefer to use a vector based program to create the artwork.

- The art work is separated by colour, and we select appropriate vinyl to use in our transfers. Different types of heat transfer vinyl may be layered over each other to achive the desired effect.

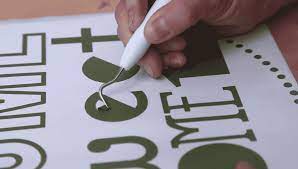

- For each transfer, we create a cutting instruction file. Sometimes this is in a generic DXF format which our vinyl cutter understands and can import, or otherwise the cutting instructions are created directly by the vinyl cutter software by tracing a raster image.

- The heat transfer vinyl sheets are then cut by a vinyl cutter. Heat transfer vinyl is very thin, and comes layered against a stiff transparent backing sheet. Only the thin layer is cut, and the pieces of vinyl that we don’t want to transfer must first be removed- a process called “weeding“.

- After weeding a transfer sheet, it is ready to be affixed to the garment by applying heat and pressure. We use a heat press to control the temperature and pressure as well as the time needed to achieve a good bond. This step is repeated for each vinyl layer.

Garments having heat transfer vinyl applied can look amazing, and the vinyl is quite durable in the wash. However, it is best to not subject heat transfer vinyl to high temperatures or exessive friction, and due care should be taken while washing vinyl prints.

0 Comments